| |

| Product Advantages |

- Modular Construction: High power, coolant, servo, fieldbus, and discrete signal capabilities are built into separate modules making maintenance easy - increasing commonality and flexibility for the customer.

- Extremely High Moment Capacity and Strength: The QC-1310 utilizes the same proven locking mechanism as the QC-310 Series Tool Changers - exceeding 2300 kg robot load specifications.

- Internally Routed Cabling: Supports integrated valve and control module options - making it easy to add and remove modules.

- Stack Height when Locked: 5.20 inch (132.2 mm) (Does not include required interface plate).

- Integrated lock and unlock sensing available.

|

|

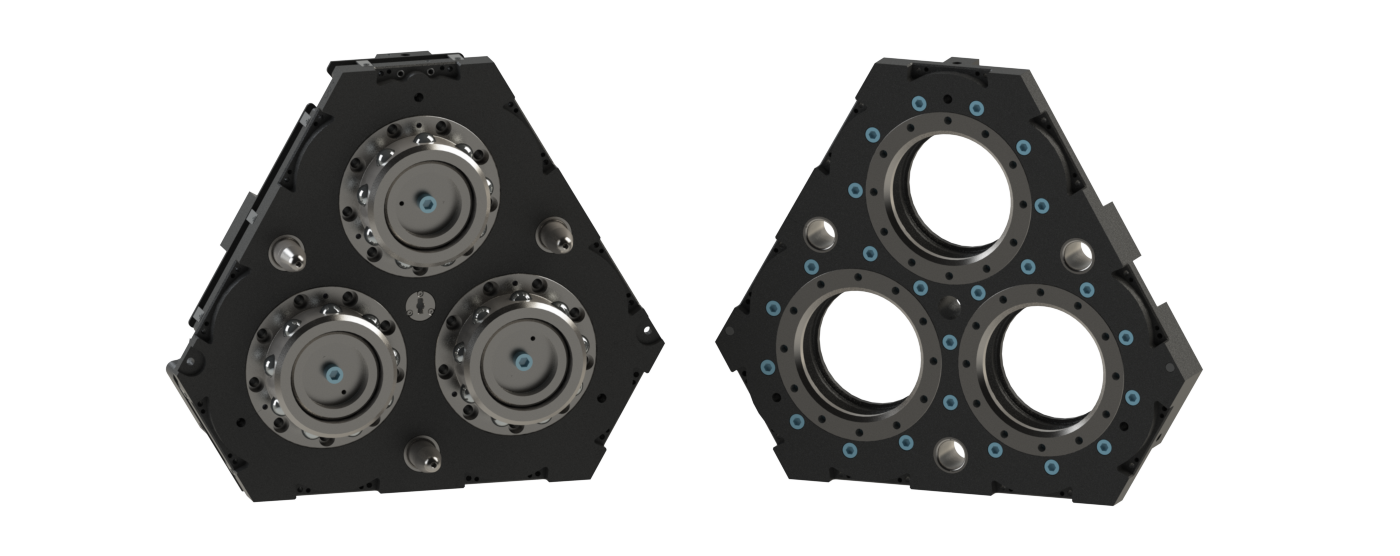

QC-1310 Tool Changer (Master and Tool)

|

|

Suggested Payload Limit: |

6600 lb |

|

Locking Force @ 80 psi (5.5 bar): |

26000 lb |

|

Static Moment Capacity (X & Y): |

97500 lbf-in |

|

Static Moment Capacity (Z): |

111000 lbf-in |

|

Positional Repeatability - (X, Y, & Z): |

0.0006 in |

|

Weight - when coupled: |

142 lb |

|

Maximum distance between Master & Tool plate before locking at 87 psi (6 bar): |

0.065 in |

|

| 9630-20-1310.pdf |

QC-1310 Tool Changer Drawing

|

|

|

Control and Signal Modules

| CYP1 | PROFINET Modules | | CYP1 PROFINET Module provides safe and reliable control over your tool changer. It comes feature rich with connectors for PROFINET to control the tool changer as well as downstream devices, integrated web server for easy diagnostics and control, tool ID switch, tool changer status inputs, and is safety focused with ATI’s tool stand interlock technology. | Flat A with JU10 or JU11 | Yes |

| DB10Z1-M,DB10-T,DB13-T | DeviceNet Quick-Connect Modules | | Quick Connect Capable DeviceNet Module with (2) Mini Conn for DeviceNet and Aux. Power Interface, TSI on Tool, Arc Prevention applied to Aux1, Aux2, and CAN V+ power. Lock/Unlock/RTL Sensing, LED Cables on Master. Tool-ID from Tool module also supported. | Flat A with J-module | No |

| DL16 | PROFINET Modules | | PROFINET Module with integrated Ethernet switch, D-Coded 4-Pin M12 connector for PROFINET communication, 5-Pin Mini Connector for US1 and US2 power, TSI on the Tool, Arc Prevention applied to US1 and US2 power. Lock, Unlock, and RTL sensing with LED cables on the Master. Tool-ID from the Tool module also supported. | Flat A with J-module | No |

| SA10 | Discrete Modules | | Discrete, 24-Pin MS3102 Connector, Supports NPN Lock, Unlock, and RTL Sensors (RTL in Series), No Integrated Valve Control, No Tool-ID or TSI on Tool. | Flat A with J-module | No |

| SA12-M,SA2-T | Discrete Modules | | Discrete Module, 19-Pin MS3102 Connector, Supports PNP Lock, Unlock, and RTL Sensors, No Integrated Valve Control | Flat A with J-module | No |

| SA2,SA3 | Discrete Modules | | Discrete Module, 26-pin Amphenol, 19-pin Block, Supports Lock/Unlock/R1/R2 Sensors, Tool ID on Tool side. (Not intended for use with an integrated valve.) | Flat A with J-module | No |

| SC29 | Discrete Modules | | Harting Module, Supports Servo Power and Redundant Encoder and Ethernet Signals, Supports L/U/R1/R2 Sensors and Integrated Valve, Supports TSI on the Tool with no RTL bypass. | Flat A with J-module | No |

| SC30 | Discrete Modules | | Discrete Module, 25-Pin HAN-D Harting Connector, 5-Pin Minifast Aux Power and 4-Pin M12 D-Coded Connector with Redundant PROFINET Pass-Through, Supports L/U/R1/R2 Sensors and Integrated Valve, 0-9 Rotary Switch Tool-ID, Supports TSI with no RTL bypass on the Tool | Flat A with J-module | No |

| SC32 | Discrete Modules | | Harting Module with Redundant Wiring, Supports Servo Power and Encoder Signals, PROFIBUS/DeviceNet Pass-through, Supports L/U/R1/R2 Sensors and Integrated Valve, Supports TSI on the Tool and Master. | Flat A with J-module | No |

| SC7 | Discrete Modules | | Harting Module, Supports Servo Power and Encoder Signals, PROFIBUS/DeviceNet Pass Thru, Supports L/U/R1/R2 Sensors and Integrated Valve, 0-9 Tool-ID, Supports TSI on the Tool | Flat A with J-module | No |

| SC8 | Discrete Modules | | Harting Module that supports Servo Power and Encoder Signals, PROFIBUS Pass Thru, Supports L/U/R1/R2 Sensors and Integrated Valve, Supports TSI on Tool | Flat A with J-module | No |

| SD2 | Discrete Modules | | Discrete Module with M23, 17-pin connector, Supporting PROFIBUS I/O Block and TSI on Tool | Flat A with J-module | No |

| VA2 | Discrete Modules | | Discrete Module, 26-pin Amphenol, 19-pin Block, Supports L/U/R1/R2 sensors and Integrated Valve, works with SA Tool-side modules, TSI on Master | Flat A with J-module | No |

| VA6 Family | Discrete Modules | | Discrete Module, 26-Pin Amphenol, 19-Pin Block, Supports L/U/R1/R2 Sensors with Integrated Valve Pass-through

VA6-M Supports TSI on the Master Side and Works with SA Series Tools | Flat A with J-module | No |

| VA7 Family | Discrete Modules | | Discrete Module, 26-Pin Turck M27 Connector, 19-Pin Block, Supports L/U/R1/R2 Sensors with Integrated Valve Pass-through.

VA7-M Supports TSI on the Master Side and Works with SA Series Tools | Flat A with J-module | No |

| VB11 | Discrete Modules | | Discrete Module, Supports L/U/R1/R2 PNP Sensors and Integrated Valve, 35-Pin DDK (MS Style) Connector, TSI on Tool, 0-9 Tool-ID, 22 Pass-Through | Flat A with J-module | No |

| VB12-M,VB13-M,VB12-T | Discrete Modules | | Discrete Signal Module with 36-Pin PT Bayonet Connector, TSI on Master, Supports L/U/R1/R2 PNP Sensors and Integrated Valve (R1 and R2 in Series). (VB13-M connector mounted on Right Angle Spacer Block.) | Flat A with J-module | No |

| VB18 | Discrete Modules | | Discrete Signal Module w/35-pin Amphenol on Master, 24-pin Amphenol on Tool. 5-pin Aux Power, 4-pin PROFINET pass-through, 17-pin and 26-pin blocks. | Flat A with J-module | No |

| VB2 | Discrete Modules | | Discrete Module, 26-pin Amphenol, 19-pin Block, Supports L/U/R1/R2 Sensors and Integrated Valve,TSI on Tool | Flat A with J-module | No |

| VB5 | Discrete Modules | | Discrete Module, 19-pin Amphenol, 19-pin Block, Tool Side Tool Stand Interlock, 10 Pass-Throughs, NPN (sinking) Locked, Unlocked, and RTL sensors | Flat A with J-module | No |

| VB7 Family | Discrete Modules | | Discrete Module, 26 Pin Amphenol, 19-pin Block, Supports L/U/R1/R2 Sensors w/ Integrated Valve Pass-Through (uses single or double solenoid valve), TSI on Tool and Tool-ID (Mates with VB Series Tools) | Flat A with J-module | No |

| VB7Z1 Family | Discrete Modules | | Discrete Signal Module with 26-Pin Amphenol, 19-pin Block, Supports L/U/R1/R2 Sensors with Integrated Valve Pass-yhrough (Uses Double Solenoid Valve) **Supports Tool Stand Interlock on Tool Side. | Flat A with J-module | No |

| VB8 | Discrete Modules | | Discrete Module, Supports L/U/R1/R2 NPN Sensors and Integrated Valve, 37-Pin DDK Connector, TSI on Tool, 0-7 Tool-ID | Flat A with J-module | No |

| VD2 | Discrete Modules | | Discrete Module, 26-pin Amphenol, Remote I/O Connection, 19-pin Block, Supports L/U/R1/R2 Sensors and Integrated Valve, TSI on Tool | Flat A with J-module | No |

| VF2 | Discrete Modules | | Discrete, 26-pin Amphenol, 19-pin Block. Supports L/U/R1/R2 Sensors and Integrated Valve. VF2-M Supports TSI on the Tool Side | Flat A with J-module | No |

| VG3 | PROFIBUS Modules | | Discrete PROFIBUS Pass-through Module | Flat A with J-module | No |

| VJ4 | Discrete Modules | | Interbus Power Pass-through and I/O Connection Module with Arc Prevention | Flat A with J-module | No |

| VK2 | Discrete Modules | | IO-Link Module with (4) M12 5-Pin Connectors for I/O Link Pass-Thru, (3) M12 5-Pin Connectors for Valve Control and Locked, Unlocked, and Ready-to-Lock Sensor Inputs. Supports Integrated Valve Control. | Flat A with J-module | No |

|

Electrical Modules

| GD4 | Electrical Modules | | Electrical Module with and with 5-position adjustable M12 4-Pin Connector | Flats B, D | No |

| GF19 Family | Electrical Modules | | 19-pin, 3 Amp/125VAC electrical module with M16-style quick-disconnect connector and five position swivel | Flats B, D | No |

|

High-Current Modules

| PA16 | Primary Current Modules | | (3) Contacts, #2 wire, 200 Amp, 600V Rating Primary Current Module | Flats B, C, D | No |

| PA2 | Primary Current Modules | | (3) Contacts, #2 wire, 200 Amp, 600V Rating Primary Current Module | Flats B, C, D | No |

| PA5 | Primary Current Modules | | (3) Contacts, #2 wire, 180 Amp, 600V Rating Primary Current Module (Master side) Mates to 9121-PA2-M | Flats B, C, D | No |

| PB2 | Primary Current Modules | | (2) Contacts, #2 wire, 200 Amp, 600V Rating Primary Current Module | Flats B, C, D | No |

| PB4 | Primary Current Modules | | Primary Current Module, (1) contacts, #2 wire, 200A rating | Flats B, C, D | No |

| PC2 | Primary Current Modules | | (5) Contacts, #2 wire, 200 Amp, 600V Rating Primary Current Module | Flats B, C, D | No |

| PC5 | Power Modules | | Power Module, 150 Amp, 5-Contact, #4 Contact Bases | Flats B, C, D | No |

| PH3 | Primary Current Modules | | Power Module, (3) 600A, 800V Contacts, #2 to #4/0 Cable | Flats B, C, D | No |

|

Other Modules

| JJ10 | Adapter Assemblies | | Dual Ledge Mount Adapter Module | Flats B, C, D | No |

| JJ16 | Adapter Assemblies | | Rail Style, Ledge Mount Adapter, 7-Positions | Flats B, C, D | No |

| JJ2 | Adapter Assemblies | | Adapter Assembly - Used to mount Single or Dual J16 pattern modules to QC | Flats B, C, D | No |

| JJ3 | Adapter Assemblies | | Single or Dual J16 Mounting Adapter Assembly (5" Adapter width) | Flats B, C, D | No |

| JJ6 | Adapter Assemblies | | Spacer Module Adapter - Use opposite NA2/NA3 Tool Hooks | Flats B, C, D | No |

| JL3,JL4 | Alignment Modules | | Gross alignment module, adapts single or dual J16 pattern modules to QC. | Flats B, C, D | No |

| JM2 | Adapter Assemblies | | Adapter Assembly - Used to mount PG0, PN2, or HA6 modules to QC | Flats B, C, D | No |

| JM4 | Adapter Assemblies | | Adapter Assembly for V300 Module | Flats B, C, D | No |

| Jxx Lock/Unlock Air Adapter with RTL Sensor Inputs | Air and Valve Adapters | | Lock/Unlock Air Adapter with Lock/Unlock/RTL sensor inputs with stainless steel hardware. | Flat A - Use with Tool Side Spacer Assembly | Yes |

| UF2 | Other Modules | | Camera Kit - Consists of GB8 Electrical Module, R4 Electrical Module, and JJ14 Mounting Adapter Assembly | Flats B, C, D | No |

|

Pneumatic and Fluid Modules

| AA2 | Air Modules | | (2) 1/2 NPT self-sealing ports (Master side), (2) 1/2 NPT self-sealing or pass-through ports (Tool side), Air Only Module | Flats B, C, D | No |

| AB2 | Air Modules | | 3/8 NPT Ports - (8) self-sealing ports (Master side), (8) self-sealing ports (Tool side), Air Only Module | Flats B, C, D | No |

| AC2 | Air Modules | | (4) 3/8 NPT self-sealing ports (Master side) and pass-through (Tool side), and (2) 3/4 NPT vacuum ports (Master and Tool side) | Flats B, C, D | No |

| ADx | Air Modules | | Air only module with self-sealing ports = AD2, AD3, AD4, AD5. Air only module with pass-through ports = AD6, AD7. | Flats B, C, D | No |

| AF2 | Air Modules | | (8) G 3/8 (BSPP) pass-through ports - Air Only Module | Flats B, C, D | No |

| AG2 | Air Modules | | (4) G 3/8 (BSPP) self-sealing ports (Master side) and pass-through (Tool side), and (2) G 3/4 (BSPP) vacuum ports (Master and Tool side) | Flats B, C, D | No |

| AH2 | Air Modules | | Air Module with G 3/8 (BSPP) Ports - (8) self-sealing ports (Master side) and (8) self-sealing ports (Tool side) | Flats B, C, D | No |

| AK2 | Air Modules | | (10) G 1/4 (BSPP) self-sealing ports - Air Only Module (Master and Tool Sides) | Flats B, C, D | No |

| AL2 | Air Modules | | (2) G 3/4 (BSPP) self-sealing ports - Air Only Module | Flats B, C, D | No |

| AM2 | Air Modules | | (2) G 1/2 (BSPP) Ports, 2 Self-sealing Ports | Flats B, C, D | No |

| AN2 | Air Modules | | Pneumatic module with (6) 3/8 NPT self-sealing ports and (2) 1/2 NPT pass-through ports | Flats B, C, D | No |

| AP2 | Air Modules | | (4) 1/2 NPT self-sealing (AP2 Master and Tool) or pass-through (AP8 Tool) ports - Air Module only | Flats B, C, D | No |

| AQ2-M,AQ2-T,AQ7-T | Air Modules | | (4) G 1/2 (BSPP) self-sealing (AQ2-M/T) and pass-through (AQ7-T) ports - Air Module only | Flats B, C, D | No |

| AQ3-T | Air Modules | | (1) G 1/2 (BSPP) self-sealing port - Air only module (Mates with FH6-M) - Tool side only | Flats B, C, D | No |

| AR2 | Air Modules | | (10) Rc 1/4 (BSPT) self-sealing ports - Air Only Module (Master and Tool Sides) | Flats B, C, D | No |

| AR3 | Air Modules | | (8) Rc 3/8 (BSPT) pass-through ports - Air Only Module | Flats B, C, D | No |

| AR4 | Air Modules | | Pneumatic Module with Rc 3/8 (BSPT) ports:

AR4 Master - (8) self-sealing ports

AR4 Tool - (8) self-sealing ports | Flats B, C, D | No |

| AR8 | Air Modules | | Pneumatic Module with (2) Rc 1/2 (BSPT) self-sealing ports, 3/8 valves | Flats B, C, D | No |

| AS6 | Air Modules | | Pneumatic Module with (10) G 1/8 (BSPP) Pass-Through Ports | Flats B, C, D | No |

| AV7 | Air Modules | | (4) G 3/4 (BSPP) Vacuum Pass-through Modules | Flats B, C, D | No |

| AV9 | Vacuum/Air Modules | | Vacuum Pass-through Module with (1) 2" NPT axial port spaced 163mm from QC | Flats B, C, D | No |

| AW2 | Air Modules | T | Air Module, (3) 1/8 NPT, (2) 1/4 NPT Pass-through Ports | Flats B, C, D | Yes |

| AW2 | Air Modules | M | Air Module, (3) 1/8 NPT, (2) 1/4 NPT Pass-through Ports | Flats B, C, D | Yes |

| FC2 | Fluid/Air Module | | G 3/8 (BSPP) Ports - (8) self-sealing ports (Master side), (4) self-sealing ports and (4) pass-through ports OR (8) pass-through ports OR (8) self-sealing ports (Tool side) | Flats B, C, D | No |

| FF3 | Fluid/Air Module | | Stainless Steel Fluid/Air module with (4) 1/2 NPT self-sealing ports | Flats B, C, D | No |

| FF4,AQ5-T | Fluid/Air Module | | Stainless Steel Fluid/Air Module with (5) 1/2 NPT self-sealing ports, 3/8 Poppets | Flats B, C, D | No |

| FH10,AQ4-T | Fluid/Air Module | | Stainless Steel Fluid/Air Module with (5) G 1/2 (BSPP) self-sealing ports, 3/8" Poppets | Flats B, C, D | No |

| FH12 | Fluid/Air Module | | Stainless Steel Fluid/Air Module with (4) G1/2 (BSPP) Self-Sealing Ports, 3/8 Valve Components, Nipple Port with Radial Seal | Flats B, C, D, E, F, G, H, J | No |

| FH13 | Fluid/Air Module | | Stainless Steel Fluid/Air Module with (4) 1/2 NPT Self-Sealing Ports, 3/8 Valve Components, Nipple Port with Radial Seal | Flats B, C, D, E, F, G, H, J | No |

| FH6 | Fluid/Air Module | | Stainless Steel Fluid/Air module with (4) G 1/2 (BSPP) self-sealing ports | Flats B, C, D | No |

| FL4 | Fluid/Air Module | | Fluid/Air Modules with (5) Rc 1/2 (BSPT) Self-Sealing Ports, 3/8 Valves | Flats B, C, D | No |

| FS2 | Fluid/Air Module | | Stainless Steel Fluid/Air Module with (4) G 1/4 (BSPP) self-sealing, (2) G 1/4 (BSPP) and (4) G 1/8 (BSPP) pass-through ports | Flats B, C, D | No |

| HBx | Hydraulic Modules | | Hydraulic Module with Pressure Ratings and Pipe Threads as Listed | Flats B, C, D | No |

|

Servo Modules

| EC6 | Servo Modules | | Servo Module with (1) M23 8-pin Servo Power Connector, (1) M23 12-Pin Servo Signal Connector, (1) Turck Mini 5-Pin DeviceNet Signal Connector, and (1) Turck Mini 4-Pin DeviceNet Power Connector | Flats B, C, D | No |

| EF16 | Servo Modules | | Servo Module with (3) Amphenol Connectors and (2) M12 Eurofast Connectors on the Master side and (3) Amphenol Connectors and (2) M12 Eurofast Connectors and (1) 1/2-20 UNF Microfast Connector on the Tool side | Flats B, C, D | No |

| EF17 | Servo Modules | | Fanuc Servo Module with 7-pin Motor Power/Brk Connector and Battery Backup | Flats B, C, D | No |

| EF19 | Servo Modules | | Fanuc Servo Module with 4-Pin Power Connector | Flats B, C, D | No |

| EF50 | Servo Modules | | Fanuc Servo Module with 4-Pin Power, 17-Pin Encoder, Adaptive Weld Connects, 4-position Terminal Strip, No Brake. Tool side has 5-Pin Female Battery Backup, 4-position Terminal Strip. | Flats B, C, D | No |

| EF64 | Servo Modules | | The EF64-M/T has been designed for new FANUC motors, encoders used with new GM robots, ARO carried servo weld guns. Module passes servo motor power, FANUC encoder and secondary weld feedback. A protective, anti-tamper bracket has been added to the EF64-M to protect encoder connector and to prevent accidental disconnection. | Flats B-J | No |

| EF9 | Servo Modules | | Servo Module Assembly with FANUC/MILCO Specifications with (2 Amphenol Connectors, (1) M12 Connector, and 4-position Terminal Strip | Flats B, C, D | No |

| EN56 | Servo Modules | | Radial Electrical Module with 4-Pin Female D-Coded M12 Ethernet Connector and 4-Pin Minifast Power Connector Pass-through | Flats B, C, D, E, F, G, H, J; Apps Approval; Requires adapter rails. Rails with more than 4 positions may interfere with modules on adjacent flats. Will extend above Master and Tool body. | Yes |

| RES10B | Servo Modules | | Servo Signal Module with 12-pole, M23 Connector, STP Wiring | | Yes |

| RES17 | Servo Modules | | Servo Signal Module with 17-pole, M23 connector | | Yes |

|

|

No 3D models for this product are currently available. See your Account Representative for more information.

|

Tool Stand Mounting Options

Click

here

for a complete list of Tool Stand information and components.

|

|

|

|

|

|

|