| |

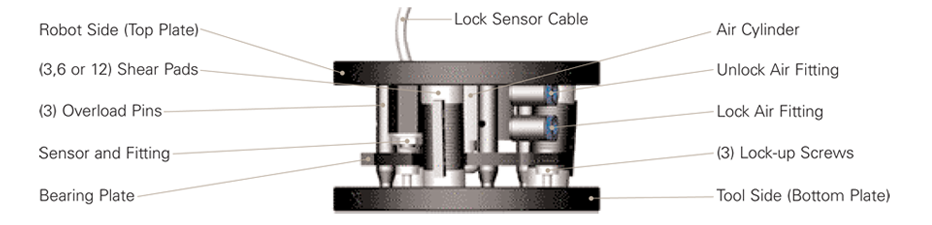

The base 9116 Series Compensator includes anodized aluminum top and bottom plates, hardened steel overload pins, and shear pads. The 000 and 100 sizes use 3 shear pads. The 200 size uses either 3 or 6 shear pads. The 400 size uses either 6 or 12 shear pads. Units with lock-up include an air cylinder, bearing plate, lock-up screws and lock-up screw bushings. Units with lock-sensing also require a sensor fitting and a cabled proximity sensor.

|

|

|

|

|

|

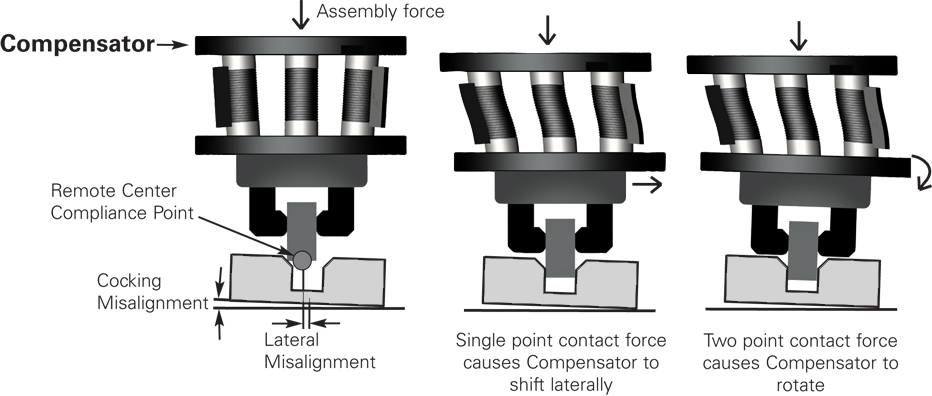

The Compensator is intended to be used in "peg-in-hole"-type operations in the vertical orientation. The "peg-in-hole" example is an application involving the insertion of one part into another. There are a variety of "peg-in-hole"-type applications that include: dowel pin insertion, mold alignment, washer insertion, the insertion of bearings into housings, and the insertion of shafts into bearings. If the Compensator is used in the horizontal orientation, over time, the shear pads will develop sag. Rubber and most rubber-like materials have memorization characteristics. Over time, the rubber material memorizes the repeated position and will return to this position. When this occurs, the shear pads have developed sag. Use of the lock-up option is recommended to prevent shear pad sag.

|

|

Excessive contact force is the main problem in many assembly applications. Excessive contact force causes galling, jamming, and broken parts. During typical assembly processes, there are three main contact forces: single-point, sliding, and two-point (see figure below). The key to reducing single-point or sliding contact force is to use a compliance device with low lateral stiffness. Two-point contact force is reduced by a compliance device with a low cocking stiffness.

Key Features and Benefits

-

Designed to provide compliance in the lateral, cocking, axial, and torsional directions.

-

Projected (remote) compliance center: The Center-of-Compliance (C-of-C) is the point in space at which a contact force will cause a translation with no rotation and a torque will cause rotation with no translation. When the C-of-C is near the insertion contact point, the insertion part axis will align with the location axis during assembly.

-

The Compensator consists of a single device with all components contained within the unit's outside diameter.

-

The 9116 Series is available in various sizes and configurations

-

The Compensator includes anodized aluminum top and bottom plates, steel overload pins, and shear pads. The 000 and 100 sizes use 3 shear pads. The 200 size uses either 3 or 6 shear pads. The 400 size uses 6 to 12 shear pads.

-

Units with lock-up include an air cylinder, bearing plate, lock-up screws, and lock-up screw bushings.

-

Units with lock-sensing also require a sensor fitting and a cabled proximity sensor.

-

9116 Series 000, 100, 200 and 400 size Compensators have two options for interfacing to a robot assembly machine. Units can be mounted by using the tapped holes on the robot side (top) plate or by bolting through the robot side (top) plate to the robot or assembly machine. The tool side (bottom) plate uses the same two methods for mounting tooling to the unit as the robot side (top) plate.

-

All units have (2) dowel pins for location on the robot (top) side plate and (2) dowel pins for location on the tool (bottom) side plate.

-

Compliance is limited by three overload pins. When the unit has reached maximum compliance, the overload pins support the load to prevent damage to shear pads.

|

|

|

|

|

|

|