|

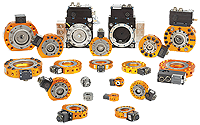

ROBOTIC TOOL CHANGERS

|

|

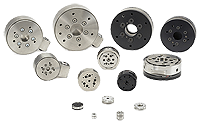

MULTI-AXIS FORCE/TORQUE SENSORS

|

|

The ATI Robotic Tool Changer provides the flexibility to automatically change end-effectors or other peripheral tooling. These tool changers are designed to function reliably for millions of cycles at rated load while maintaining extremely high repeatability.

|

|

|

The F/T force and torque sensors provide full six-axis force and torque sensing with high factor of safety. The F/T can be mounted to a robot arm or any tooling where multi-axis force/torque sensing is needed.

|

|

|

|

|

|

|

MATERIAL REMOVAL TOOLS

|

|

COBOT-READY PRODUCTS

|

|

ATI Material Removal Tools are a family of compliant deburring and finishing tools designed for a variety of applications. Air-actuated compliance overcomes part variation and makes programming quicker and easier.

|

|

|

Cobot-Ready End-Effector Kits offer users a simple and effective way to increase the flexibility of collaborative robots. These all-in-one packages feature a broad selection of robotic end-effectors that are well suited for an array of industries and application types.

|

|

|

|

|

|

|

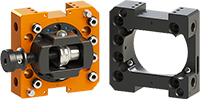

UTILITY COUPLERS

|

|

MANUAL TOOL CHANGERS

|

|

ATI Utility Couplers are designed for industrial applications where there is a need to change tools that pass utilities such as air and electrical signals in automated applications. The modular body design is capable of mounting any of ATI’s standard add-on modules.

|

|

|

Manual Tool Changers provide a cost-effective solution for quickly changing tools by hand. They feature a unique design that combines high strength, excellent repeatability and a patent-pending screw-cam locking mechanism with multiple fail-safe features.

|

| |

|

|

|

|

|

ROBOTIC COLLISION SENSORS

|

|

COMPLIANCE DEVICES

|

|

The Robotic Collision Sensor protects robotic end-effectors and robot arms from damage caused during robot crashes. Features include: automatic reset, high repeatability, large moment rotation, rugged design and low cost.

|

|

|

ATI offers three unique compliance compensators that allow your workpieces to operate more reliably in tight alignment tolerances with less effort required to design. This will save both time and money, and reduce downtime.

|