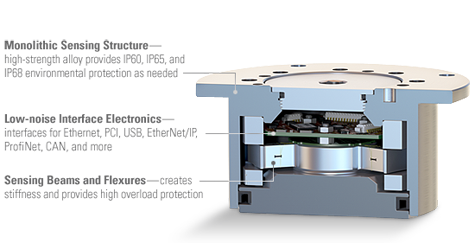

The ATI Multi-Axis Force/Torque Sensor system measures all six components of force and torque. It consists of a transducer, interface electronics and cabling.

The compact and rugged monolithic transducer uses silicon strain gages to sense forces. The transducer's silicon strain gages provide high noise immunity and allow high overload protection, which is standard on all models.

The Net F/T, DAQ F/T, Controller F/T, and TWE F/T each provide a variety of powerful functions:

-

Tool transformations

translate and/or rotate the F/T reference frame.

-

Demo software

allows configuration and basic data logging capabilities.

-

Biasing

provides a convenient way to offset tool weight.

-

Increased system throughput

is possible by reducing the number of axes of output. (Not applicable to the Net F/T or TWE F/T.)

-

Threshold detection

eases integration into industrial applications (Net F/T and Controller F/T only).

-

Integral temperature compensation

insures accuracy over a wide temperature range.

-

High overload protection

makes the F/T Transducer extremely rugged and durable as it can withstand overload of five to twenty times its sensing range.

-

High signal-to-noise ratio

provides a signal 75 times stronger than conventional foil gages. This signal is amplified resulting in near-zero noise distortion.

-

Prompt delivery

of standard F/T models.

-

Custom F/T transducers

can be designed and built to your specifications.

-

Application assistance

by experienced engineers.

|

|