|

Max Static Moment X-Y |

20 lbf-in |

|

Max Static Moment Z |

10 lbf-in |

|

Positional Repeatability X-Y |

±0.006 in |

|

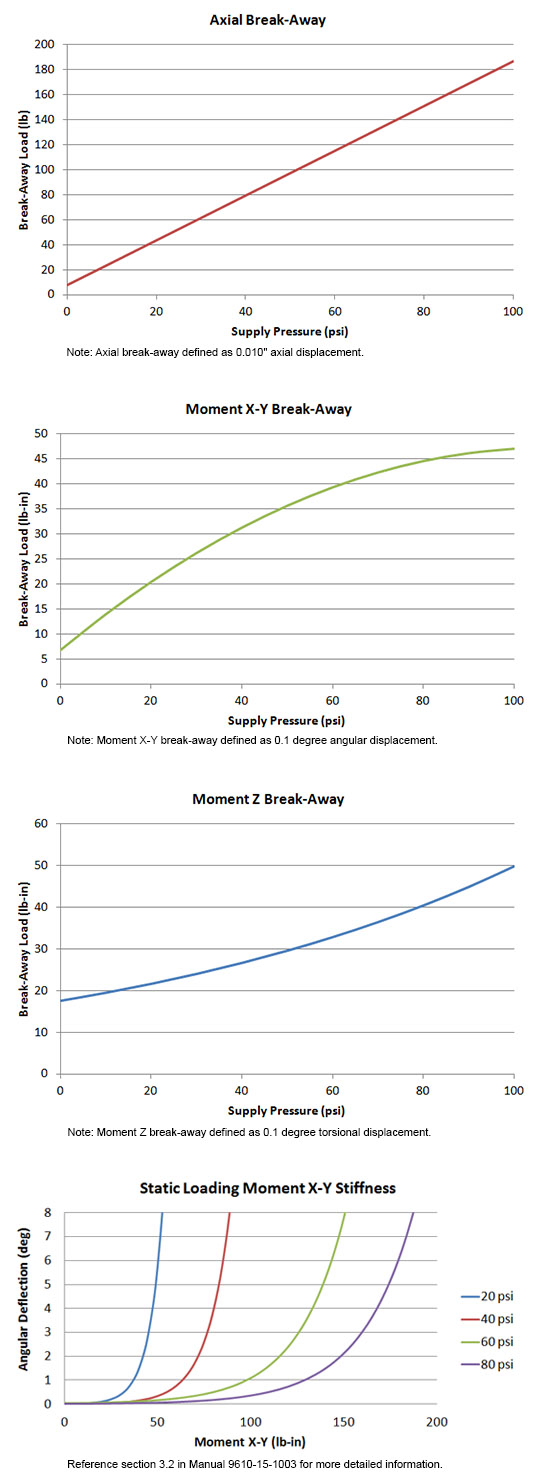

Break-Away & Compliance Stiffness |

See Performance Charts |

|

Nominal Operating Pressure |

80 psi |

|

Max Pressure for Compliance Stiffness Tuning ** |

30 psi |

|

Ambient Temperature Range |

-20 °F to 150 °F |

|

Rated Life |

1 million cycles |

|

Sensing Option |

PNP or NPN |

* Compliance limit for rated service life. Internal hard stops allow up to ± 8° but reduced spring life should be expected.

** Tune compliance stiffness by varying lock pressure between 0-30 psi. Forcing compliance above 30 psi may reduce service life.

|

|

| 9630-15-U1K-050-SA-M-2131-L.pdf |

Universal Compliance Compensator, 31.5 Boss, 50mm BC, NPN Sensor, Hardwired 5m Cable , M5 Port, 2131 Tool IP, Locking

|

| 9630-15-U1K-050-SB2-M-0000-L.pdf |

Universal Compliance Compensator, 31.5 Boss, 50mm BC, PNP Sensor, Hardwired 0.25m Cable & 90 Deg LED Pico, M5 Port, Locking

|

| 9630-15-U1K-050-SB2-M-2131-L.pdf |

Universal Compliance Compensator, 31.5 Boss, 50mm BC, PNP Lock Sensor, Hardwired 0.25m Cable & 90 Deg LED M8 Plug, M5 Port, 2131 Tool IP, Locking

|

| 9630-15-U1K-050-SB2-M-2131-L-C1.pdf |

Universal Compliance Compensator, 31.5 Boss, 50mm BC, PNP Lock Sensor, Hardwired 0.25m Cable & 90 Deg LED M8 Plug, M5 Port, 2131 Tool IP, Locking, C1 Boot

|

|

| 9610-15-1003.pdf |

Universal Compliance Compensator Manual

|

|

| UCC 50mm Mounting Pattern |

Universal Compliance Compensator, 31.5 Boss, 50mm BC, PNP Sensor, Hardwired 0.25m Cable & 90 Deg LED Pico, M5 Port, 2131 Tool IP, Locking

|

|

|