Back to Tool Changers

Case Study: Oxford Automotive (Canton, MS)

New innovation greatly reduces time and complexity for

tool changes in DeviceNet environments.

Problem:

Oxford Automotive, a Tier 1 automotive

supplier located in Canton, Mississippi, encountered some issues while

implementing a robotic cell containing Six-Axis industrial robots, ATI Quick

Change Tool Changers, and a DeviceNet network environment for tooling control.

In this cell, several industrial robots complete a variety of material handling

and welding operations, performing multiple tool changes during each and every

cycle. Each robotic end-effector has multiple I/O devices and sensors as a part

of its configuration.

Oxford’s goal was to keep cost, weight, cycle

time, and wiring to a minimum. The following were factors for this project:

-

DeviceNet physical layer

(trunkline-dropline) restrictions add design complication to ensure proper

termination at the tooling.

-

Standard DeviceNet modules on the tooling

were taking too long to come online during a tool change to meet cycle time

requirements.

-

Running discrete wires to each sensor and

actuator on the tool through the tool changer is not a viable option, as it is

ungainly and adds weight and complication to the tooling.

Oxford was experiencing delays of up to 8

seconds per tool change during a multi-change cycle when implementing current

DeviceNet technology. Due to the cycle frequency, this series of delays added

significant time to the process, to the point of being unacceptable for

production.

Oxford presented these issues to the Design

Engineers at ATI who responded with new, cutting-edge technology.

Solution:

The standard way of obtaining DeviceNet I/O

from robotic tooling is to pass DeviceNet signals through the tool changer to

the nodes on the tooling. With this method, each device on the tooling is a

node on the host network and is connected and disconnected with each tool

change cycle. As a result, using standard DeviceNet technology produces a delay

of up to 8 seconds before tool ID is achieved, adding costly delays to the

cycle.

With ATI InstaTool technology, the host

DeviceNet network ends at the tool changer master, which is connected to the

network at all times.

The tooling I/O is connected to specific

models of commercially available DeviceNet I/O blocks.

These DeviceNet I/O blocks are then connected via standard DeviceNet

wiring to the tool changer tool-side ATI InstaTool module. Since

the tooling I/O is accessed as if it were part of the tool

changer master DeviceNet node, connection delays are greatly reduced.

The tool communicates the I/O to the master with a non-DeviceNet industrial

communications protocol.

ATI has optimized the power-up sequence of

the tooling I/O devices, resulting in the tooling I/O being available to the

host network in less than 1 second -- all end-effector I/O is available on

DeviceNet by the time a tool couple operation is completed. No more waiting for

DeviceNet nodes to come up on the network.

DeviceNet -

with and without ATI InstaTool

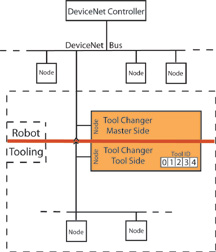

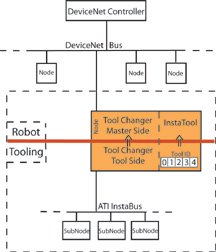

The illustrations below indicate the

fundamental differences between standard DeviceNet connectivity and the new ATI

InstaTool technology.

Standard

Network

|

Before ATI InstaTool, the DeviceNet signal passed from the DeviceNet

controller, through the master side to the tool side of the tool changer, then

on to the nodes.

With this method, each time a new tool side connection is made, up

to an 8-second start-up delay occurs before tool identification is made and the

application can continue.

|

|

ATI Solution

|

With InstaTool, the DeviceNet signal effectively stops at the tool

changer master, creating an always-on connection to that master node. Using

patent-pending high-speed technology, the master node handles all I/O

communication downstream from the master.

The result is a connect time of less than 150 milliseconds for tool

ID and under 700 milliseconds for tool I/O. Tool I/O appears at the master

node.

|

|

Results:

After implementation of ATI InstaTool, the

tool change delay has been completely eliminated. The robot moves, with tool

attached, immediately after the lock operation is completed. There has

been no observed latency on any of the control signals or sensor inputs.

Overall, Oxford is experiencing a dramatic improvement in efficiency and

productivity using InstaTool. All of the ATI Quick Change Tool Changers are

performing with the same high-level of performance as other ATI products.

Upon completion everyone

expressed their extreme satisfaction with the ATI InstaTool product.

Discussions were initiated about outfitting the entire plant with ATI InstaTool

changers.

Summary:

-

Easy to implement with new

cells or retrofit into existing cells

-

Simple, intuitive

configuration using DIP switches

-

Integrated diagnostics to aid

troubleshooting

-

Uses standard DeviceNet-type

cabling

-

Works with standard ATI Quick

Change Tool Changer models -

QC-151, 152, 201, 202, 303, 501, 502

Back to Tool Changers

|