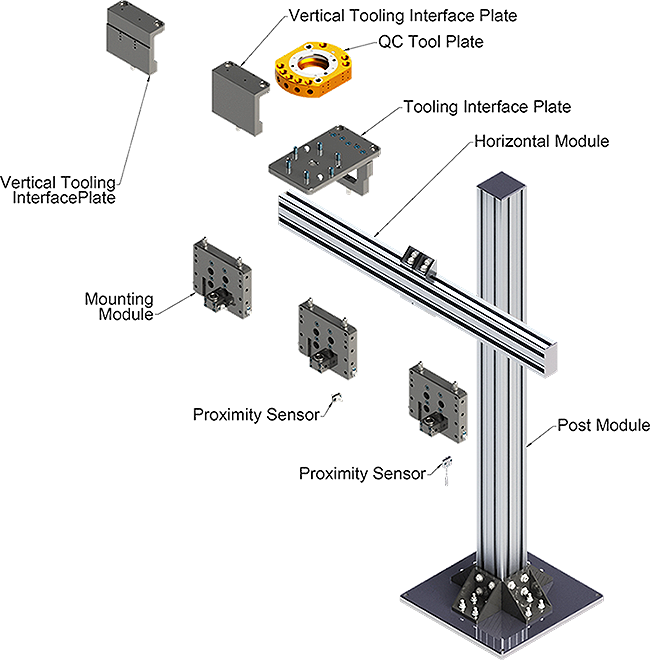

A TSM system provides for various Post Module heights, Horizontal Modules, and Horizontal Extensions to accommodate a variety of customer tooling sizes. Horizontal or vertical tooling interface plates can be used to secure the Tool Changer and customer tooling to the stand and can be used with Tool Changer models QC-40 through QC-110.

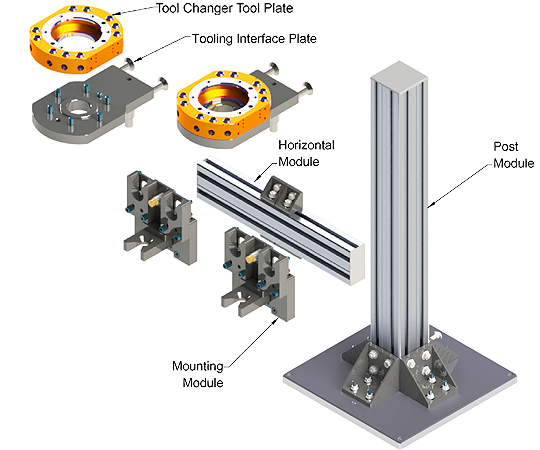

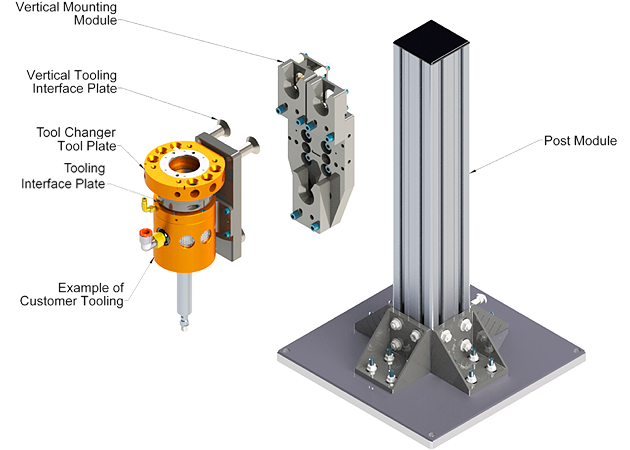

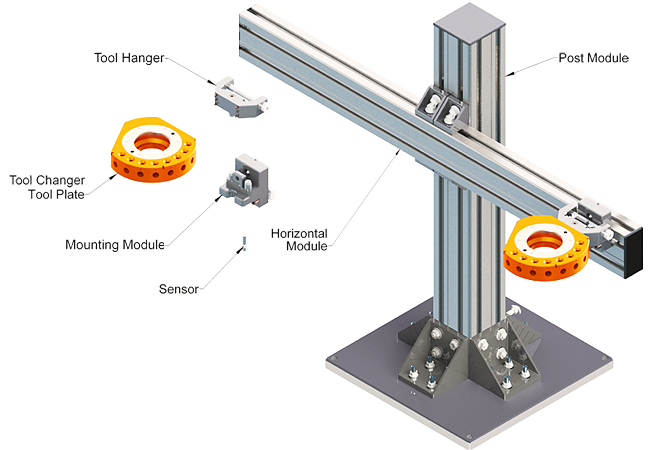

There are three distinct styles of Mounting Modules for the TSM systems, a Pin and Bushing Mounting Style, a V-Block (Vertical and Horizontal) Mounting style, and a Tool Hangar Mounting style. All styles are equally strong, equally flexible. It comes down to application-specific preferences to determine which style is the best choice.

To determine the components needed for a Tool Stand, will require knowledge of the system being designed. When selecting the Tool Stand components you will need to consider the following information:

- What model Tool Changer will be used and if add on modules will be required for the customer tooling.

- If the Tool Stand will support one or more tools and what height Post Module will be needed to accommodate the dimensions of the tooling.

- What size, shape, and Center of Gravity of end-effector and tooling.

- What mounting style Tool Stand will be used (Pin and Bushing, V-Block, or Tool Hangar).

- Will customer tooling mount directly to a Vertical Tooling Plate with an interface plate attaching the Tool Changer or will the customer tooling and Tool Changer attach directly to a Tooling Interface plate.

- Size, reach and capabilities of the robot being used.

- Area available to accommodate the Tool Stand.

|

Use the Product Index to help select the ATI part numbers associated with the desired TSM System components.

Click here to view the TSM Product Index.

Click here to see a list of Tool Stand Configuration Examples

|

|

|

|

|

The Pin and Bushing Modules are available in a rigid mounting system and are designed with two mounting patterns. Horizontal and vertical Tooling Interface Plates provide a mount for customer tooling. The Mounting module is designed to mount to the TSM Post module using T-bolts or directly to a TSL Post module for heavy tool applications. Several types of proximity sensors can be installed on the Mounting Module.

|

|

|

|

|

|

Customer tooling and the Tool Changer Tool Plate can be mounted directly to the Tooling Interface Plate. The Mounting Module provides mounting for Sensor Modules. The Horizontal Module can accommodate multiple Mounting Modules for additional tooling.

|

|

|

|

|

|

Vertical Mounting Modules with Tooling Interface Plates provide mounting for the Tool Changer Tool Plate and the customer tooling. Customer tooling can be mounted to a Tooling Interface Plate. This configuration requires the Tool Changer Tool Plate to be mounted to customers tooling or the Vertical Tooling Interface Plate using a separate tooling interface plate. The Vertical Mounting Module provides mounting for Sensor Modules.

|

|

|

|

|

|

Tool Hanger Mounting Modules with Tool Hangers provide mounting to the Horizontal Module for the Tool Changer Tool Plate. This configuration requires the Tool Changer Tool Plate to be mounted either directly to the customer tooling or using an interface plate. The Tool Hanger Mounting Module provides an integrated mounting for proximity sensors.

|

|