Spot welding aluminum is a resistance welding method used to join two or more overlapping metal sheets. Typically, two copper electrodes clamp the metal sheets together and current is passed through the material. The resultant heat generated by electrical resistance creates a pool of molten material between the copper electrode tips. When the current is stopped, the copper tips cool the spot weld, causing the metal to solidify under pressure.

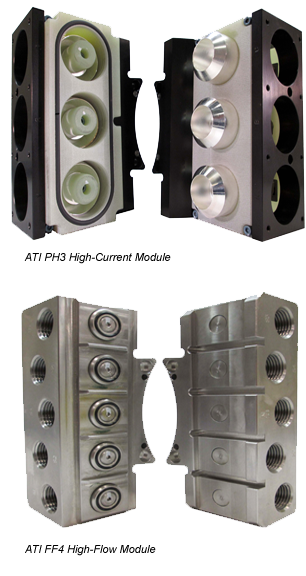

The water-cooled copper electrodes are essential to remove the surface heat quickly, accelerating the solidification of the metal. ATI’s new Tool Changer Utility Modules have been specifically engineered to accommodate these high coolant flow requirements. ATI’s FF4 module is a fluid/air module supporting five ½ inch hoses. With two feed lines and three return lines, the FF4 module can pass enough cooling water for nearly any robot-carried weld gun, allowing the weld gun to cool the electrode correctly and maintain consistent weld quality.

ATI’s new Tool Changer Utility Modules have been designed to allow for large power cable diameter and are able to handle continuous high current transfer without failure. ATI’s PH3 module is a primary current module that supports 0000 AWG or 100 mm2 cables. This is much larger than the 2 AWG or 35 mm2 cables typically used for welding steel. ATI also offers Tool Changer Utility Modules to support clinching, riveting, bolting, flow drill screws, and other joining methods commonly used for aluminum.

ATI offers a wide selection of Tool Changer models and Utility Modules to cover a variety of applications. Key features include: Excellent repeatability, high rigidity, and a lightweight and compact design. With over 20 years of robotic end-effector innovation experience, ATI’s engineering department, the largest of its kind for a robotic tooling company, is focused on developing cost-effective, state-of-the-art products and solutions.

More information on our FF4 Fluid/Air Utility Module here.

More information on our PH3 Fluid/Air Utility Module here.

More information on our Robotic Tool Changers here.