| |

There are three types of TSS systems, one is designed specifically for the QC-001 Tool Changer, and the others can be used with models QC-5 through QC-41. A TSS system provides for various Post Module heights, Horizontal Modules, or Tool Bars to accommodate a variety of customer tooling sizes. The Pin and Bushing type tool stand utilizes horizontal or vertical tooling interface plates to secure the Tool Changer and customer tooling to the stand. The Pin and Rack type tool stand uses alignment pins that attached directly to the Tool Changer Tool Plate or to an Adapter Plate to hold the Tool Changer and customer tooling to the stand. The Tool Changer and customer tooling is held in the tool stand on the Mounting Module for the QC-001 Tool Stand.

-

What model Tool Changer will be used and if add on modules will be required.

-

Number of tools the stand must accommodate.

-

Dimensions of the tooling that will be used.

-

Size, reach and capabilities of the robot being used.

-

Area available to accommodate the Tool Stand.

-

Area between tool positions required for pneumatic fittings, hoses, electrical cabling and other utilities.

Use the Product Index to help select the ATI part numbers associated with the desired TSS Small Tool Stand components.

Click here to view the TSS Product Index.

Click here to see a list of Tool Stand Configuration Examples

There are three types of TSS systems, one is designed specifically for the QC-001 Tool Changer, and the others can be used with models QC-5 through QC-41.

|

|

|

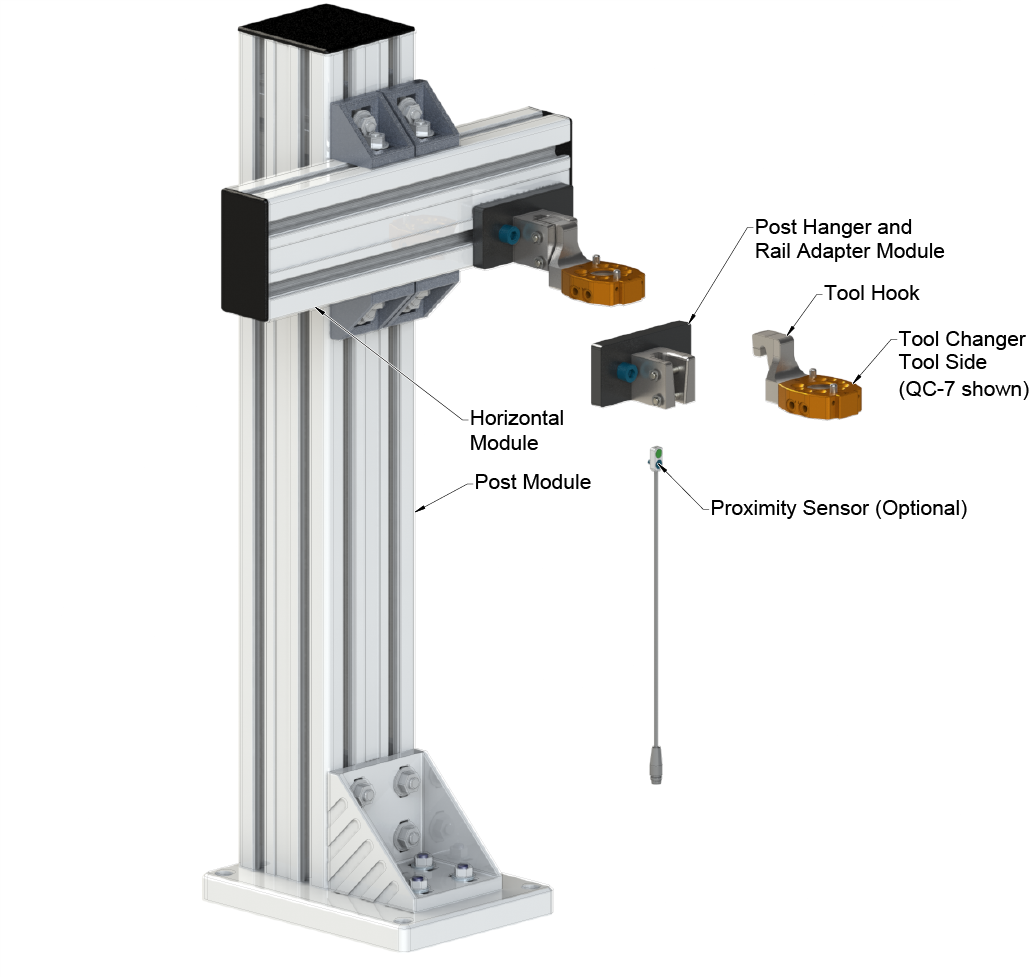

Configuring a TSS System for Hook and Hanger Mounting Modules

The TSS with hook and hanger mounting modules are compatible with ATI QC-7 Tool Changers. A post hanger and rail adapter module mounts horizontally to the horizontal module. An optional proximity sensor can be installed on the post hanger module. A tool hook module attaches to Flat B of the QC-7 Tool Changer Tool Plate.

|

|

|

|

|

|

|

|

|

|

|

|

|

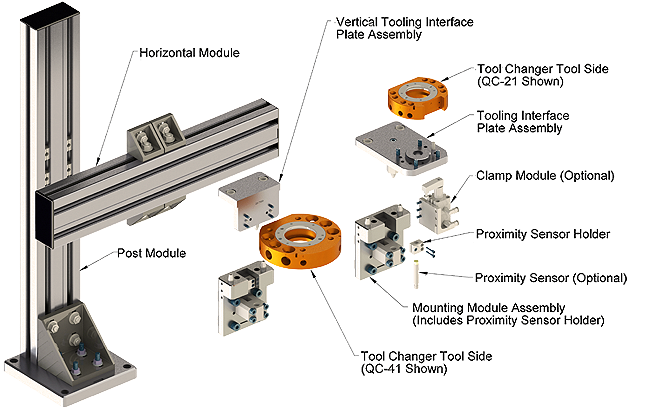

The pin and bushing tool stands offer variable spacing tool positions, tool sensing, and clamping options to provide the most flexible system for Tool Changer models QC-5 through QC-41. The Mounting Module can mount directly to the Post module for up to two tool positions, or mount to an optional horizontal module to accommodate multiple tool positions depending on tool spacing requirements. Horizontal or vertical tooling interface plates can be used to secure the Tool Changer and tooling to the stand.

|

|

|

|

|

|

|

|

|

|

|

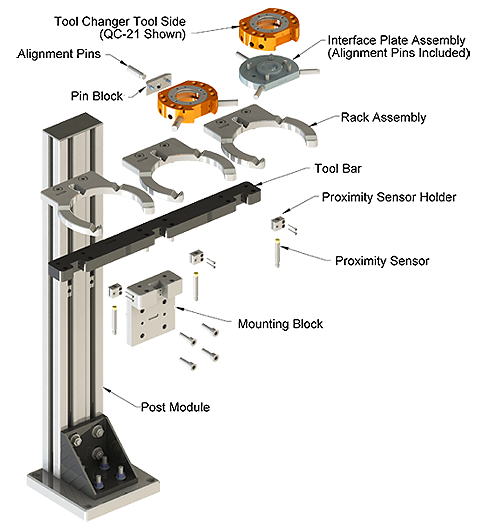

The pin and rack tool stands provide for up to six fixed tool positions for Tool Changer models QC-5 through QC-41. The Mounting Block is mounted directly to the Post module for up to two tool positions, or an adapter bar can be used to accommodate three, four, or five fixed tool positions. The Tool Changer can be supported in the rack assembly with or without an Interface plate. Rack Assemblies are used to support the Tool Changer and customer tooling in the rack. Optional Proximity sensor holders and proximity sensors can be added for tool presence sensing. A forward adapter can provide additional tool spacing from the rack.

|

|

|

|

|

|

|

|

|

|

|

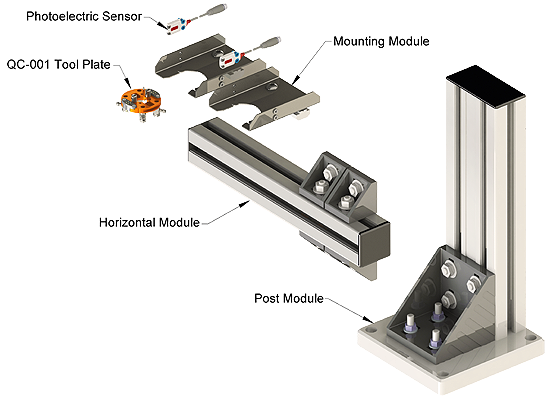

For the QC-001 model Tool Changer the Tool Stand design is very simple, there are only a few variables you will have to consider. How many tools will be needed and what size the tools will be. This will determine how many mounting modules will be needed and the length of the Horizontal Module that will be needed to support them. If Tool Stand sensing is needed you will need a Photoelectric sensor kit for each tool.

|

|

|

|

Please contact your ATI Account Manager for further clarification in selecting the proper tool stand components to fit your application 919-772-0115.

|

|

|

|