| |

|

|

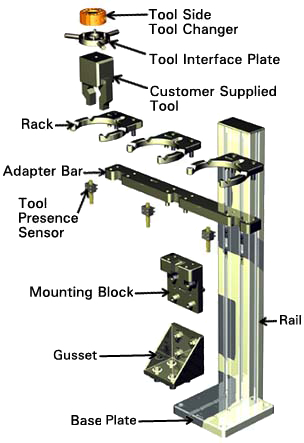

The ATI TSS Small Tool Stand System consists of the following components. These

all will assemble to form a complete assembly, or can be used separately as your

application requires. Click the link below to view the

web page for information

on how to configure a TSS system and for configuration examples.

Configuring a TSS System

|

The TSS Interface Plate Assembly provides an interface between your tool and the Tool Changer. The Interface plates are sized specifically to correspond with the Tool Changer and TSS Rack. The TSS Interface Plate assembly includes 3 stainless steel alignment pins that interface with the V-grooves on the TSS Rack. The standard interface plates are sold blank to allow customers to machine their own tooling bolt patterns. ATI can provide specific tooling patterns upon request.

The TSS Rack Assembly includes a rigid “U” shaped plate with V-grooves that interface with stainless steel alignment pins mounted to the tooling. This Groove-Pin Combination allows for compliance in the horizontal plane, and also provides repeatable tool positioning. The assembly includes mounting hardware, and is designed to mount to the TSS Mounting Block, TSS 3, 4 or 5 Tool Adapter Bar, or TSS Forward Adapter. The Rack can be mounted to any other surface that has corresponding mounting features.

Currently there are 4 types of adapter bars. The 3-Tool Adapter Bar mounts to the Mounting Block and can hold up to three TSS Racks. The 4- and 5-Tool Adapter Bar is similar but can hold up to 4 or 5 TSS Racks at once respectively. Each Adapter Bar also allows for the attachment of a Proximity Sensor Holder for each Rack. The third adapter bar is the Forward Adapter Bar. This is used when your tooling requires extra clearance from the Rail.

Tool Presence Sensing uses an 8mm diameter proximity sensor. This option is highly recommended to detect when the tool is properly nested in a Rack.

The TSS Mounting Block Assembly mounts to the Rail. It can be positioned anywhere along the rail to the desired height. Once the desired height is determined, it is recommended that dowel holes be drilled into the rail as specified in drawing # 9230-20-1675. These dowels are needed to ensure accurate positioning over the life of the stand. Then the TSS Rack, or 3, 4, or 5 Position Tool Adapter Bars can mount to the Block. The Block also can accommodate a Proximity Sensor Holder.

The TSS Rail and Gusset assemblies mount to the Base Assembly and include alignment and mounting hardware. The standard TSS Rail is an aluminum extrusion (Bosch 45x90 series) and is approximately 24 inches long. Customers can request custom lengths when ordering. The TSS Gusset (Bosch type 90x90) provides additional structural support at the Tool Stand Base.

The TSS Base Assembly consists of a square aluminum machined base plate and hardware that attaches to the TSS Rail, and TSS Gusset Assembly. The base provides a secure foundation on which to build the Tool Stand System.

|

|

|

|

|