|

InstaToolT

New

innovation greatly reduces time for tool changes in

DeviceNet environments.

DeviceNetT

is a popular industrial communications bus used to connect

industrial devices and reduce or eliminate time-consuming discrete

wiring. DeviceNetT

is a popular industrial communications bus used to connect

industrial devices and reduce or eliminate time-consuming discrete

wiring.

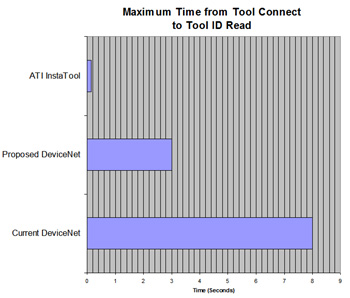

The Problem

With the obvious benefits of DeviceNet technology comes the

inevitable delay that occurs during tool

identification - as long as 8 seconds at each tool change. The

cumulative effect of these delays is a loss of production time. This

compounded effect becomes a factor in reducing manufacturing

productivity.

In an effort to minimize this delay, a new DeviceNet standard is

being proposed which could potentially reduce this delay to 2 to 3

seconds. This is still a noticeable delay during an application

process.

ATI InstaToolT solves the problem.

The

Solution: ATI InstaToolTM Technology The

Solution: ATI InstaToolTM Technology

With ATI InstaToolT, long delays for tool identification and tooling

I/O are a thing of the past.

By using ATI InstaToolT technology, the new tool-side module

communicates tool ID and tooling I/O to the master/robot module in

just tenths of a second after tool changer coupling. There is no

longer a need to establish a DeviceNet node on the tool side, which

in turn prevents power-ups from negotiating lengthy DeviceNet

protocol sequences. Tooling is available on the network in under a

second.

Best of all, there are no costly upgrades of DeviceNet scanner and

master controller equipment required to enjoy the substantial

benefits of ATI InstaToolT.

Product Advantages

-

Near-Instant

Connection and Tool Identification: With InstaTool, tool ID

occurs within 150 milliseconds, as compared to up to 8 seconds

using current technology. Tool I/O is available within 700

milliseconds.

-

Reduction in Time:

No delay means overall cycle time is reduced and production is

increased. This advantage is heightened in applications with

multiple tool changes.

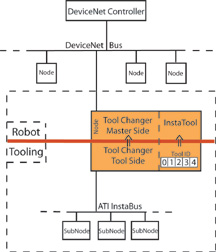

Reduced DeviceNet Node Management: With ATI InstaToolT and

InstaBusT technology, the tool changer master node handles 160 I/O

communications downstream, resulting in fewer DeviceNet nodes to

manage.

-

Tool ID Passes

Through Master: Systems with multiple masters and tools can

positively identify which tools are connected to each master.

-

Tool Stand

Interlock (TSI): A tool stand interlock feature is provided on

the tool/slave side for safer tool changer operation. The TSI

allows uncoupling only when the tool changer is in the tool stand.

Customers have the option to choose mechanical or proximity sensor

switches to close the TSI circuitry.

-

Additional Safety

Features: Additional DeviceNet inputs are provided to identify

unsafe operating conditions. Customer operating software can be

programmed to halt tool changer operation when unsafe conditions

exist.

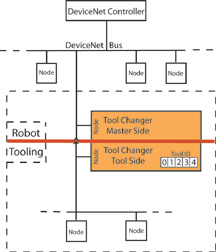

DeviceNet - with and without ATI InstaToolTM

The illustrations below indicate the fundamental differences between

standard DeviceNet connectivity and the new ATI InstaToolT

technology.

| Current Network

Before ATI InstaToolT, the

DeviceNet signal passed from the DeviceNet controller, through

the master side to the tool side of the tool changer, then on

to the nodes. With this method, each time a new tool side

connection is made, up to an 8 second start-up delay occurs

before tool identification is made and the application can

continue. |

|

| |

|

ATI Solution

With InstaToolT, the DeviceNet signal effectively stops at the

tool changer master, creating an always-on connection to that

master node. Using patent-pending high-speed technology, the

master node handles all I/O communication downstream from the

master. The result is a connect time of less than 150

milliseconds for tool ID and under 700 milliseconds for tool

I/O. Tool I/O appears at the master node. |

|

Top |