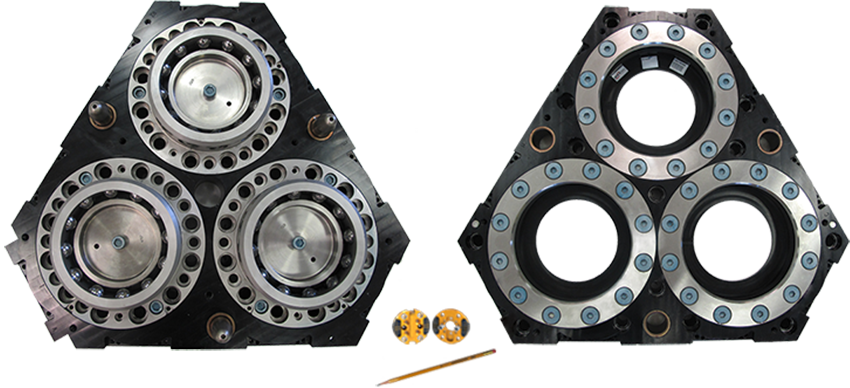

ATI Industrial Automation has developed a Heavy Duty Tool Changer that can handle extremely large payloads up to 4080 kg (9000 lbs). Compatible with existing Heavy Automation Tool Changer utility modules, the modular construction of the QC-1510 Tool Changer allows integration into applications requiring high-power, coolant, servo, DeviceNet™, Ethernet, PROFINET, and discrete signal capabilities by incorporating separate modules that can be mounted on any of the nine available flats. This common module mounting pattern makes maintenance easy—increasing uniformity and flexibility.

The QC-1510 uses a common Lock/Unlock air supply and a Lock/Unlock sensing method that allows end-users the option to receive one signal from the Tool Changer or one from the three individual locking mechanisms. In operation, three Ready-to-Lock sensors detect when the Tool plate is within 1.65 mm (0.065 in) of the Master plate (signaling Ready-to-Lock) ensuring that the Tool plate and Master plate are parallel. No-Touch Locking™ technology allows a small plate separation when locking. All locking parts are made of 58 HRC stainless steel and are designed for superior reliability, repeatability, and strength.

Along with developing the largest Tool Changer, ATI has recently developed their smallest Tool Changer yet. The QC-001 Micro Tool Changer features an extremely compact and lightweight design for high-speed "spider" or delta robots. The QC-001 weighs less than 4.3 ounces (122 grams) while allowing for 3 pound (1.4 kg) payloads.

ATI offers a wide selection of Tool Changer models to cover a variety of applications. Key features include: Excellent repeatability, high rigidity, and a lightweight and compact design. With over 20 years of robotic end-effector innovation, ATI’s engineering department, the largest of its kind for a robotic tooling company, is focused on developing cost-effective, state-of-the-art products and solutions.

More information on our QC-1510 Heavy Automation Tool Changer here

More information on our QC-001 Micro Tool Changer here

More information on our Robotic Tool Changers here

ATI's largest and smallest Tool Changers, the QC-1510 and QC-001