|

ATI Develops New Ethernet Tool Changer Control Modules

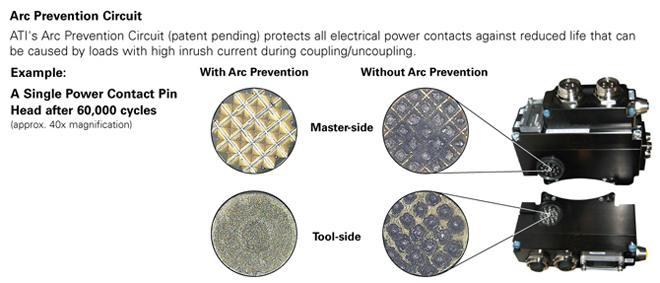

Arc Prevention Technology Protects Power Contacts

Apex, NC,

January 21, 2010

ATI Industrial Automation has developed a new series of Tool Changer Modules that control and communicate with ATI's Heavy Automation Robotic Tool Changers using EtherNet/IPTM while passing DeviceNetTM network and power to the Tool-side. This provides for utilization of EtherNet/IP on the robot up to the Tool Changer and short connection times to the Tool-side equipment by using DeviceNet Quick Connect equipment on the tooling. ATI Industrial Automation has developed a new series of Tool Changer Modules that control and communicate with ATI's Heavy Automation Robotic Tool Changers using EtherNet/IPTM while passing DeviceNetTM network and power to the Tool-side. This provides for utilization of EtherNet/IP on the robot up to the Tool Changer and short connection times to the Tool-side equipment by using DeviceNet Quick Connect equipment on the tooling.

The new DKD Ethernet Modules also feature ATI's Arc Prevention Circuit (patent pending) which protects all electrical power contacts against reduced life that can be caused by loads with high inrush current during coupling/uncoupling. Provided through a connector on the Tool module, ATI's Patented TSI (Tool Stand Interlock) technology prevents uncoupling of the tooling when not safely nested in the Tool Stand.

Product Features Include:

- Integrated EtherNet/IP interface.

- DeviceNet pass-through with Arc Prevention Circuit.

- Two AUX Power pass-throughs with Arc Prevention Circuit.

- TSI (Tool Stand Interlock) prevents uncoupling of the tooling when not safely nested in the Tool Stand.

- Tool-ID, adjustable from 0 to 9.

- Integrated web server for Tool Changer configuration and status.

- Internal pin block for valve electrical connections.

- Multi-function design requires fewer cables and connectors and allows for a compact assembly.

More information on our DKD EtherNet/IP Tool Changer Modules here.

More information on our Robotic Tool Changers here.

|