Norkol Converting Corporation is one of the nation's leading converters and distributors of commercial printing papers. Norkol turned to system integrator Mapleroc Industries and automation partners ABB Robotics and ATI Industrial Automation to implement a new cutting and finishing system to speed up their process. In the past, Norkol utilized traditional paper converting equipment that unwinds, slits and then re-winds paper to new dimensions. This equipment, while typically producing new widths of paper with clean cuts, works at an inefficient slow pace.

Norkol Converting Corporation is one of the nation's leading converters and distributors of commercial printing papers. Norkol turned to system integrator Mapleroc Industries and automation partners ABB Robotics and ATI Industrial Automation to implement a new cutting and finishing system to speed up their process. In the past, Norkol utilized traditional paper converting equipment that unwinds, slits and then re-winds paper to new dimensions. This equipment, while typically producing new widths of paper with clean cuts, works at an inefficient slow pace.

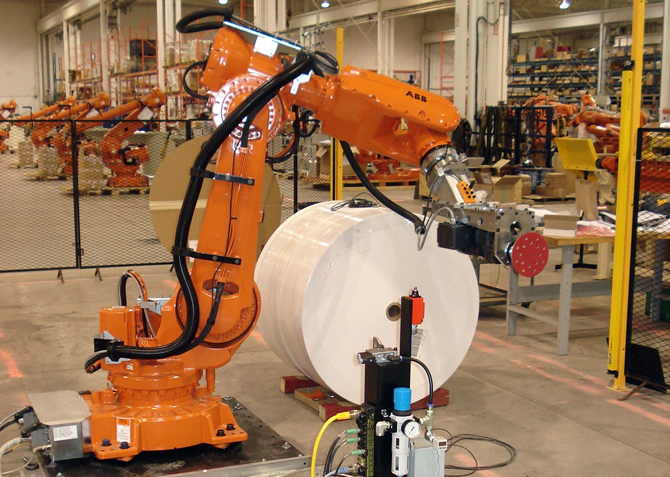

Together the partners developed and integrated a new fully automated cutting and finishing system using Mapleroc's RollRazor® cutting technology, ABB Robots and ATI's Multi-Axis Force/Torque Sensors. The system utilizes a finely honed and engineered blade to cut parent rolls of paper in their rolled state in one pass, cutting them to press-ready roll sizes in 3 minutes all without the need to un-wind and re-wind the paper. It is the fastest paper roll converting machine currently available. To complete the robotic cutting application, the newly developed Robotic Roll Finishing System creates a fully-automated, high-precision force-controlled roll-finishing station. With the cut roll moved into place, the robot equipped with the sanding head smooths the edges utilizing the ATI Force/Torque sensor technology to provide force feedback. This enables the robot to feel and have a sense of touch just as a human would. This sense of touch allows the robot to make quick adjustments in real-time to maintain a constant contact force. The Robotic Roll Finishing System with its force/torque sensing capability eliminates safety risks for employees and offers manufacturers a quick and efficient method of finishing the roll to the standards required by the customer. The system allows the robots to address all roll sizes and unfinished surfaces automatically, eliminating the need for manual set-up.

“Our goal at Mapleroc is to manufacture roll converting equipment with the best available technologies that improves our customers runability and printability of their paper. We are doing this while dramatically lowering the cost of roll converting.” commented Mapleroc’s Todd Morrison. “We have been very pleased with the new cutting and finishing system as it is faster and eliminates problems for most applications. We are currently evaluating and considering replacing additional re-winders with this more efficient system,” said Mike Maloy of Norkol.

In addition to the robotic roll finishing application, force control is ideal for many other applications including difficult assembly, machining, and finishing tasks that previously required skilled personnel or complex assembly machines. Force/torque sensors are used throughout the industry for product testing, robotic assembly, grinding and polishing. Force control provides excellent robotic contour following, such as in grinding, or deburring, to insure the correct force is being applied. It is also used for robotic material handling to verify product weight and collision-free placement. In research, ATI’s sensors are currently being used in robotic surgery, haptics, rehabilitation, neurology, and many other applications.

View the complete article here.

More information on our Force/Torque Sensors here.

More information on our Norkol here.