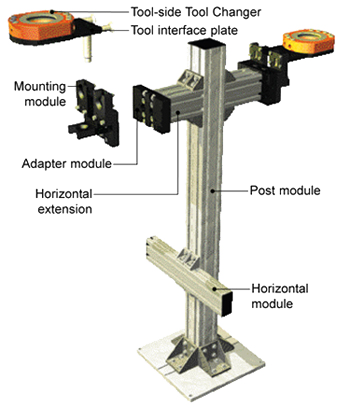

The ATI TSM Medium Tool Stand System consists of the following components. The components can be assembled to form a complete assembly or partially to fit your configuration requirements. Click the link below to view the web page for information on how to configure a TSM system and for configuration examples.

|

|

Configuring a TSM System

|

|

|

|

The TSM Mounting Modules are specifically designed to interface with the Tooling Plate assemblies for each corresponding Tool Changer. Mounting Modules mount onto the included TSM Rail components, or you may use the existing bolt patterns to mount to your custom fixture. Mounting Modules come in two configurations: Horizontal or Vertical orientation. Click the link below to see the TSM Product Index for tool interfacing option details.

TSM Product Index

The TSM Tooling Plate Assemblies attach to your tooling. Alignment Pins are included with the Tooling Plates. Customers can either specify their tool attachment requirements at the time of purchase or choose Blank Tooling Plates and machine their own tooling bolt patterns.

Choose from several TSM Post and Rail Modules to build your specific Stand configuration. The Post Modules, Horizontal Modules, and Horizontal Extensions are aluminum-extruded rails (Bosch-series). Alignment and mounting hardware is included. Basic standard rail lengths are offered, but customers may specify other lengths.

TSM Adapter Modules are specifically designed adapter plates with mounting hardware included that attach Mounting Modules to Rail or Post Modules. Adapter Modules extend the flexibility of the Tool Stand System to cover a myriad of configuration options.

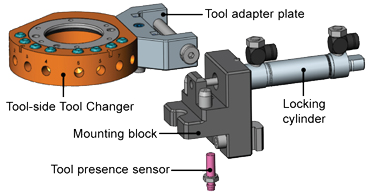

This option is highly recommended to detect when the tool is properly nested in the stand. The TSM sensor module uses an 18mm diameter proximity sensor. The sensors can be ordered direct from ATI or from any preferred sensor distributor.

|

|

The Locking Medium Tool Stand Mount is a secure option for tool storage. It includes a machined block with steel locating pins. The assembly includes mounting hardware and is designed to mount to any horizontal extruded rail, such as the TSM-HM series rails. The Mounting Block can also be mounted directly to any custom plate designed by the customer. The assembly features a double-acting locking air cylinder. After the robot uncouples from the Tool Changer and air pressure locks the cylinder, the tool is fully secured in the stand. Air pressure is required to unlock the cylinder, releasing the tool from the block. This locking feature is ideal for applications that have offset tool center-of-gravity, and applications where tooling hoses and cables work against the weight of the tool during normal tool storage situations.

|

|

It is extremely important to protect your valuable tooling from process debris. Welding and grinding applications produce tough grit and grime that attack the wear surfaces of the tooling. ATI boasts the toughest locking mechanisms in the industry, but it is equally important to cover the unused tools while they are stored so that the life of the products is maximized. Debris protection is an important feature and there are many options to choose from for the TSM product line. Fully-actuated shields are available in a wide range of styles and sizes with foam seals or leather side guards. Use the stand-alone Tool covers and have your robot pick them up and attach them to the tooling as a cost-effective method of protection.

|

V-shaped 4140 Hardened Steel Blocks receive corresponding steel alignment pins. Mount to extruded rail components or bolt directly onto custom fixtures. The Alignment Pins are also sold separately as replacement parts or for custom applications.

|