ATI Industrial Automation has been awarded patent #8,005,570 for an improved Robotic Tool Changer Locking Mechanism. This innovation builds on the unmatched reliability, safety and strength of ATI’s Robotic Tool Changer product line. In industrial use for over twenty years, ATI Tool Changers feature a spring-less Fail-Safe Locking Mechanism that prevents inadvertent unlocking, further increasing reliability. This Fail-Safe feature eliminates the need for a spring in the design, which can be an unreliable component.

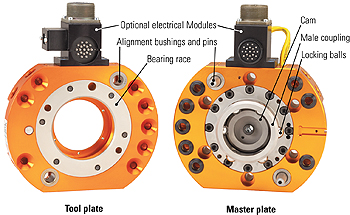

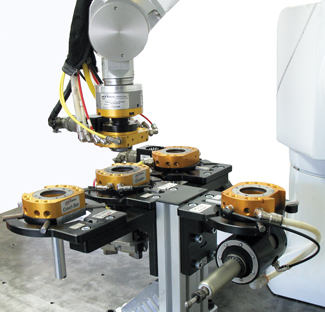

ATI Tool Changers provide flexibility to robot applications by allowing the robot to automatically change end-effectors (e.g., grippers, vacuum cup tooling, pneumatic and electric motors, weld guns, and more). The Tool Changer consists of a Master plate and a Tool plate. The Master plate, installed on the robot arm, locks to the Tool plate with a pneumatically-driven Locking Mechanism. This Locking Mechanism uses a multi-tapered cam employing the newly-patented Fail-Safe surface. The Master plate allows for the passage of pneumatic and electrical connections to the Tool plate. Each Tool plate is attached to a unique end-effector. The Tool plate interfaces with the Master plate pneumatic and electrical connections and passes them on to the end-effector.

ATI Fail-Safe vs Spring Design

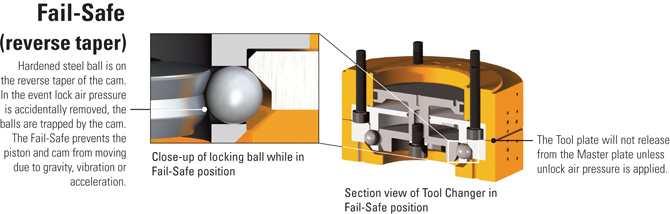

Typically used in other tool changer designs, a spring provides the force to hold the Master plate and Tool plate together if air pressure is accidentally removed. If the spring force is overcome during a crash or high-acceleration move, the spring can allow the Master plate to unlock and drop the Tool. ATI’s Fail-Safe prevents inadvertent unlocking by utilizing a multi-tapered cam that traps the locking balls in the Master plate, preventing them from moving, which keeps the Tool plate locked to the Master plate. The Fail-Safe prevents inadvertent unlocking due to gravity, vibration, or acceleration. Also, springs can fatigue and fail, possibly jamming the locking mechanism closed or releasing the Tool. ATI’s Fail-Safe Locking Mechanism is made of hardened stainless-steel components and features a “self-compensating” design that accommodates the slight wear that may be exhibited over millions of cycles. The use of a spring greatly increases the pressure necessary to unlock the tool changer. ATI Tool Changers require significantly less pressure to unlock the Tool plate from the Master plate.

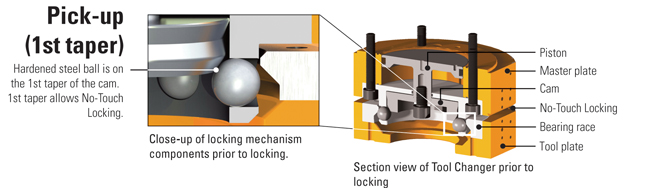

Pick-up

Coupling of the Master plate and the Tool plate is achieved through a patented, precision, high-strength, stainless-steel Locking Mechanism. ATI’s patented No-Touch Locking™ technology allows separation between the Master plate and Tool plate when they are within the specified distance. A pneumatically-actuated piston drives the multi-tapered cam into contact with the locking balls. The 1st taper of the cam forces the locking balls outward and into contact with the bearing race, pulling the Tool plate up toward the Master plate, initiating the locking process.

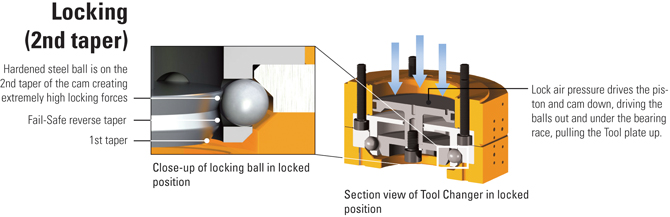

Locking

Air pressure supplied from the lock port on the Master plate drives the internal piston and cam, forcing the locking balls outward, through the male coupling. The 2nd taper of the cam forces the locking balls further out and under the bearing race, pulling the Tool plate to the Locked position. The 2nd taper of the cam creates extremely high locking forces, securely coupling the Master plate and Tool plate together to provide high load carrying capacities. Hardened stainless-steel alignment pins on the Master plate and hardened stainless-steel bushings on the Tool plate provide positional accuracy and high repeatability.

Fail-Safe

The ATI Tool Changer Locking Mechanism has a Fail-Safe feature that prevents the Tool plate from releasing from the Master plate if lock air pressure is accidentally removed. The reverse taper of the cam prevents the locking balls on the Master plate from moving-thus keeping the Tool plate locked to the Master plate. The Fail-Safe feature prevents the piston and cam from moving due to gravity, vibration, or acceleration. Unlock air pressure or manual override is required to unlock the Tool plate from the Master plate.

Robert Little, chief operating officer at ATI states, "ATI is focused on engineering the best products in the world, then improving them further.” ATI offers a wide selection of Tool Changer models to cover a variety of applications. All ATI Tool Changers feature their patented Fail-Safe Locking Mechanism and No-Touch Locking™ technology. Key features include: Excellent repeatability, high rigidity, and a lightweight and compact design. With over 20 years of robotic end-effector innovation, ATI’s engineering department, the largest of its kind for a robotic tooling company, is focused on developing cost-effective, state-of-the-art products and solutions.

More information on our Robotic Tool Changers here.

Read the full patent here.