|

Tool Changers contribute to Chrysler's flexible manufacturing success

ATI's QC-210 and 310 Heavy Automation Tool Changers are a significant part of the process

Apex, NC,

February 7, 2007

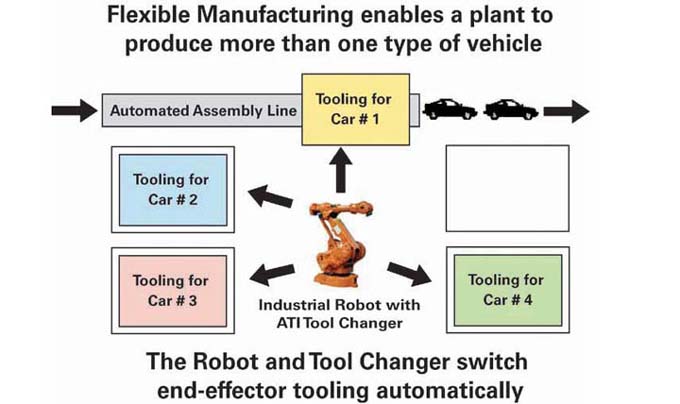

In the pursuit to cut costs and increase flexibility, Chrysler Group has adopted a flexible manufacturing process where robots and tool changers are utilized in manufacturing multiple cars on one assembly line. Traditionally, most assembly plants are limited by their ability to produce only one car model. When demand for the model being produced drops, the plant works at less capacity. And when the plant is re-tooled for a new model, much of the costly equipment is scrapped. Chrysler Group's Belvidere (IL) Assembly Plant was the first to undergo the flexible manufacturing transformation. Equipped with over 700 ABB robots and 237 Master-side and 576 Tool-side ATI Heavy Automation Tool Changers, one plant can now build a different model car automatically by switching end-effector tooling. This approach allows three different models to be built by one plant, making the plant much more responsive to demand. In addition, the new flexible plant re-fit only cost about two-thirds that of a traditional plant re-fit.

As stated in the As stated in the

Wall Street Journal "We are now starting to see the results of the new flexible manufacturing process that we believe is a competitive advantage for the Chrysler Group," said Frank Ewasyshyn, Executive Vice President - Manufacturing. "Thanks to Belvidere's ability to build multiple models off one assembly line, we expect the production of three all-new models to cost significantly less than the initial investment we made in the plant to build one product."

ATI's engineering staff, the largest of its kind for a robotic tooling company, has created many solutions to resolve the engineering obstacles associated with this type of state-of-the-art manufacturing environment. The Chrysler Group will continue to execute its flexible manufacturing process plant-by-plant. For more information on ATI's Tool Changer products, follow this link here.

Reference Links:

Wall Street Journal: Chrysler Gains Edge by Giving New Flexibility to Its Factories

Plant Engineering: DaimlerChrysler: Building cars, building teams

Industry Week: Chrysler's Winning Formula: Hot Cars + Flexibility

|