|

Patent Awarded to ATI for Arc Prevention Technology

Eliminates Damaging Arcing Effect That Can Occur During Tool Changes

Apex, NC,

July 20, 2014

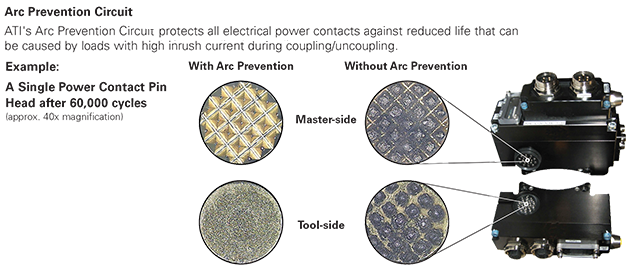

ATI Industrial Automation was recently awarded a patent for their Arc Prevention technology which completely eliminates the damaging arcing effect that can occur when passing power through a tool changer.

When passing power to inductive/capacitive loads through a tool changer, power should be turned off during the tool change to prevent arcing. Arcing can occur when high inrush-current loads on the tool side cause a small arc to form between the pin block contacts. Over time, arcing can cause damage to the power contacts. Some customers are not able to turn the power off during a tool change, so ATI invented a way to automatically cut off the power when changing tools. ATI's Patented Arc Prevention technology prevents arcing and therefore extends the life of pin block contacts.

ATI's Arc Prevention technology is available on a variety of ATI Tool Changer Control/Signal Modules that support a variety of bus network types including: DeviceNet, EtherNet/IP PROFINET, and more. ATI's Arc Prevention technology can also be used in a variety of non-bus network systems where power cannot be switched during a tool change.

ATI offers a wide selection of Tool Changer models and Utility Modules to cover a variety of applications. Key features include: Excellent repeatability, high rigidity, and a lightweight and compact design. With 25 years of robotic end-effector innovation, ATI’s engineering department, the largest of its kind for a robotic tooling company, is focused on developing cost-effective, state-of-the-art products and solutions.

More information on our Robotic Tool Changers here.

More information on our Control and Signal Modules here.

|